ST Centreless belt grinding and polishing systems

LOW BUDGET GRINDING AND POLISHING MACHINES FOR ROUND PRODUCTS

Centerless system for the finishing of cylindrical products available with grinding belts or polishing units and with full automatic cycle and set up on diameter.

One of the main advantages of the system is the possibility of being configured to work a wide range of products, for example can be processed either particularly small diameters or short parts,

The machine is offered with dedicated handling system to work automatically from bundle to bundle, supplied according to any dimensions and type of the products to be processed.

STX is provided with an advanced control system for the working pressure, adjustable independently for each unit according to the required performances and tools used.

To reduce the diameter adjustment time and to monitor the correct positioning of the machine this is operated by the main panel with the simple input of diameter value.

Safety and sound proofing enclosures. Close the working area and prevent the access to the operator during automatic working cycle.

A touch screen panel integrated into the cabin and positioned in Front of each unit through a friendly graphic interface will help the operator to supervise the production cycle and to operate localised fine tuning of the machine during working operations.

CENTERLESS Grinding and Polishing of Round products, TUBES, PIPES and BARS

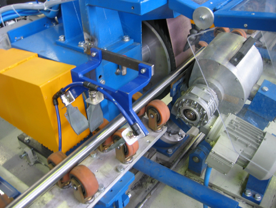

ST grinding unit

ST with 2 Units

ST line for round tubes

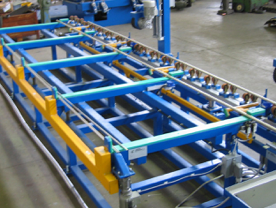

HANDLING AND ANCILLARY EQUIPMENT

STX is an automatic machine designed with modular system componible according to customer demand with the following parts and accessories.

-

a)BELT GRINDING units.

-

b)BRUSHING OR MIRROR POLISHING units.

-

c)COMPLETE HANDLING systems either for short and long products for example such as roller conveyors or transporting belts and dedicated loading and unloading devices.

-

d)Automatic loading and unloading tables or cradle.

-

e)PACKING MACHINE to close each single pipe into a plastic bag.

-

f)FILTRATION SYSTEM, sized on the machine dimensions and performances, filters of different types are added to treat either the coolant liquid , working mists and dusts generated during the production cycle.

-

g)SPECIAL DEVICES to be considered on a case by case basis will be possible to integrate in the machine measure devices for dimensions and roughness.

ST loading and roller conveyors

ST polishing set up

ST short parts